Kysb Mechanical Seal Double Suction Centrifugal Water Pump

KYSB Mechanical Seal Double Suction Centrifugal Water Pump PRODUCT OVERVIEW:According to market needs, KYSB Mechanical Seal Double Suction Centrifugal Water Pump are developed in the broad absorption of advanced technology. Its remarkable characters are as follows: perfect, excellent general model, ......

Send Inquiry

Product Description

KYSB Mechanical Seal Double Suction Centrifugal Water Pump

PRODUCT OVERVIEW:

According to market needs, KYSB Mechanical Seal Double Suction Centrifugal Water Pump are developed in the broad absorption of advanced technology. Its remarkable characters are as follows: perfect, excellent general model, novel structure, convenient repair. KYSB type water pumps currently produced by our company have fall into more than 40 categories, nearly 400 specification products. We had improved pump impeller and impeller diameter to lead to its impact framework and increasing efficiency. In the spectrum performance range, we can provide any water pump that meets users' need for pump head and flow.

Sophisticated products and complete quality control, reach domestic advanced standard. We have IS09001 certificate so we can ensure its quality.

This series of water pumps are in accordance with lS02548C, GB321 6C, GB/T5657 standard.

APPLICATIONS:

KYSB Mechanical Seal Double Suction Centrifugal Water Pump is widely used in city water supply and drainage, urban water supply; water supply and drainage of central heating system; iron and steel metallurgy, petrochemical refineries, paper mills, oil fields, power plant, airport construction, chemical plants, textile mills, sugar refinery, chemical plant, power plant water supply and drainage, the factory, mine fire water supply system, air conditioning system of water supply, farmland irrigation and drainage, and all other kinds of water engineering.

- KYSB Mechanical Seal Double Suction Centrifugal Water Pump

- Widely used in many scopes

- High quality and best prices

- KYSB 5hp Diesel Engine Water Pompa

WORKING CONDITIONS:

- Rotation speed: 990, 1480 or 2960rpm

- Voltage: 380,6kv or 10kv

- Inlet and outlet diameter: 150-600mm (in accordance with GB/T17241.66-1998 flange standard)

- Flow: 68-3975m3/h

- Head: 6-230m

- Temperature: fluid temperature ≤80, ambient temperature≤40

- Working pressure: 1.0Mpa (G) (Hsp≤75m) or 1.6MPa (Hsp>75)

- Medium permitted: clean water, contact to us for special requirement

- Pipe parts for seal: can't be installed under condition of above 0.03MPa (G)

PHOTO OF Centrifugal Water Pump AVAILABLE):

MODEL MEANING OF KYSB WATER PUMP:

KYS B 200 - K 6 / 258 - F

| KYS | KYSB Mechanical Seal Double Suction Centrifugal Water Pump |

| B | New Model split centrifugal pump |

| 200 | Inlet Diameter (mm) |

| - | - |

| K | Impeller model K-Original impeller Z-Modification of impeller |

| 6 | 1/10 of impeller specific speed |

| / | / |

| 258 | Specification code |

| - | - |

| F | Special type: Rotation direction of pump is anticlockwise.(Standard type:No marks) |

STRUCTURE OF KYSB CENTRIFUGAL WATER PUMP:

| Impeller |

|

| Pump body |

|

| Bearing |

|

| Shaft |

|

| Base |

|

| Shaft Sealing |

|

ASSEMBLY:

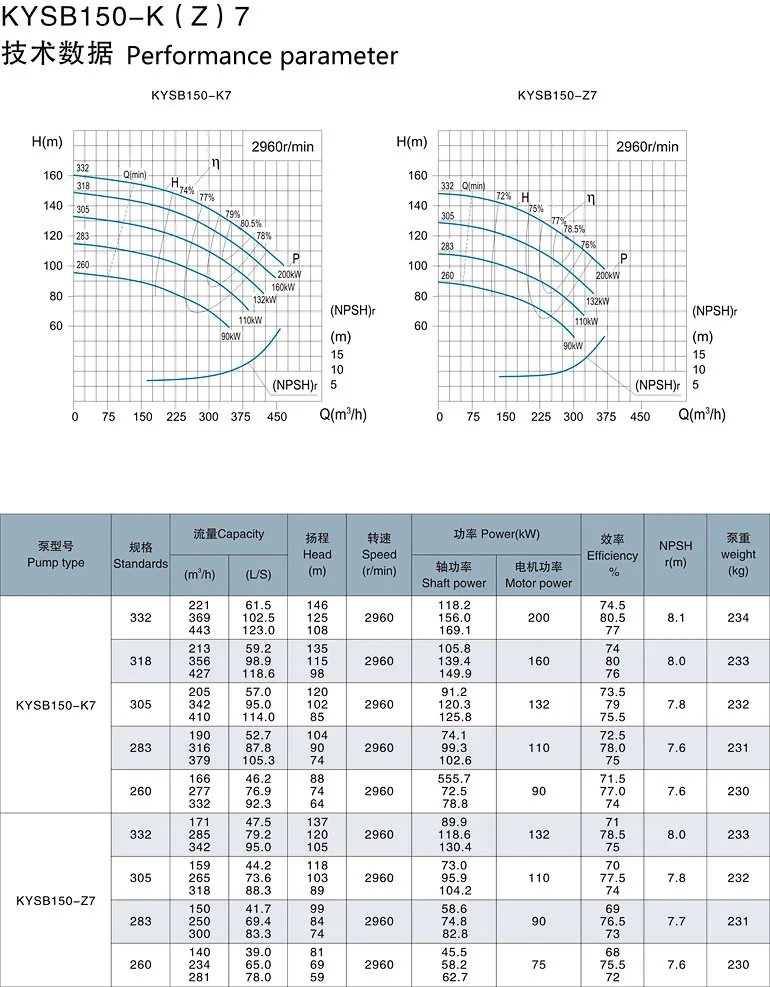

CURVE OF KYSB WATER PUMP:

PERFORMANCE PARAMETER OF KYSB200-K(Z)4 WATER PUMP:

Pump Type | Standards | Capacity | Head (m) | Speed (r/min) | Power (kW) | Efficiency % | NPSH r(m) | Weight (kg) | ||

(m3/h) | (L/S) | Shaft Power | Motor Power | |||||||

KYSB200-K4 | 338 | 168 280 336 | 46.7 77.8 93.3 | 200 193 180 | 2960 | 145.2 207.2 245.7 | 250 | 63 71 67 | 10.5 | 369 |

360 | 155 258 310 | 43.1 71.7 86.1 | 176 165 155 | 2960 | 121.7 167.9 195.2 | 220/200 | 61 69 67 | 10.3 | 365 | |

328 | 142 236 284 | 39.4 65.6 78.9 | 146 138 132 | 2960 | 95.7 132.3 157.0 | 160 | 59 67 65 | 10.1 | 361 | |

305 | 132 220 250 | 36.7 61.1 69.4 | 131 120 1 12 | 2960 | 81.2 108.9 119.1 | 132 | 58 66 64 | 9.9 | 359 | |

283 | 124 207 245 | 34.4 57.5 68.1 | 1 1 3 1 03 1 01 | 2960 | 66.9 89.3 | 110 | 57 65 63 | 9 7 | 357 | |

388 | 143 238 285 | 39.7 66.1 79.2 | 196 190 176 | 2960 | 123.1 175.9 206.9 | 220 | 62 70 66 | 10.3 | 368 | |

360 | 124 208 250 | 34.4 57.8 69.4 | 1 72 1 60 1 51 | 2960 | 96.8 133.2 158.1 | 160 | 60 68 65 | 10.0 | 363 | |

KYSB200-Z4 | 328 | 156 196 236 | 43.3 54.4 65.6 | 136 133 127 | 2960 | 99.6 107.5 129.5 | 132 | 58 66 63 | 9.9 | 359 |

286 | 114 190 224 | 31.7 52.8 62.2 | 109 102 98 | 2960 | 60.4 83.7 98.0 | 110 | 56 63 61 | 9.8 | 356 | |

Company profile

Shanghai Kaiyuan Pump Industrial Co., Ltd. is one of leading pump manufacturers in Shanghai, China. specializing in producing all kinds of water pumps with various and complete specifications. We have two production bases of which are located in Fengxian district.

Our company has passed the Test Certification issued by Shanghai Mechnical & Electrical Testing Center and the evaluation of '' ISO9001:2008'' Quality Control Certificate. With intergrated features of scientific research, development, manufacturing, sales and services, Shanghai Kaiyuan is very unique in the pump producing field and enjoys a high reputation.