Home > Products > Centrifugal Pump > Kve250-500 Single Stage Energy Saving Pulp Pump for Sugar Industry

Kve250-500 Single Stage Energy Saving Pulp Pump for Sugar Industry

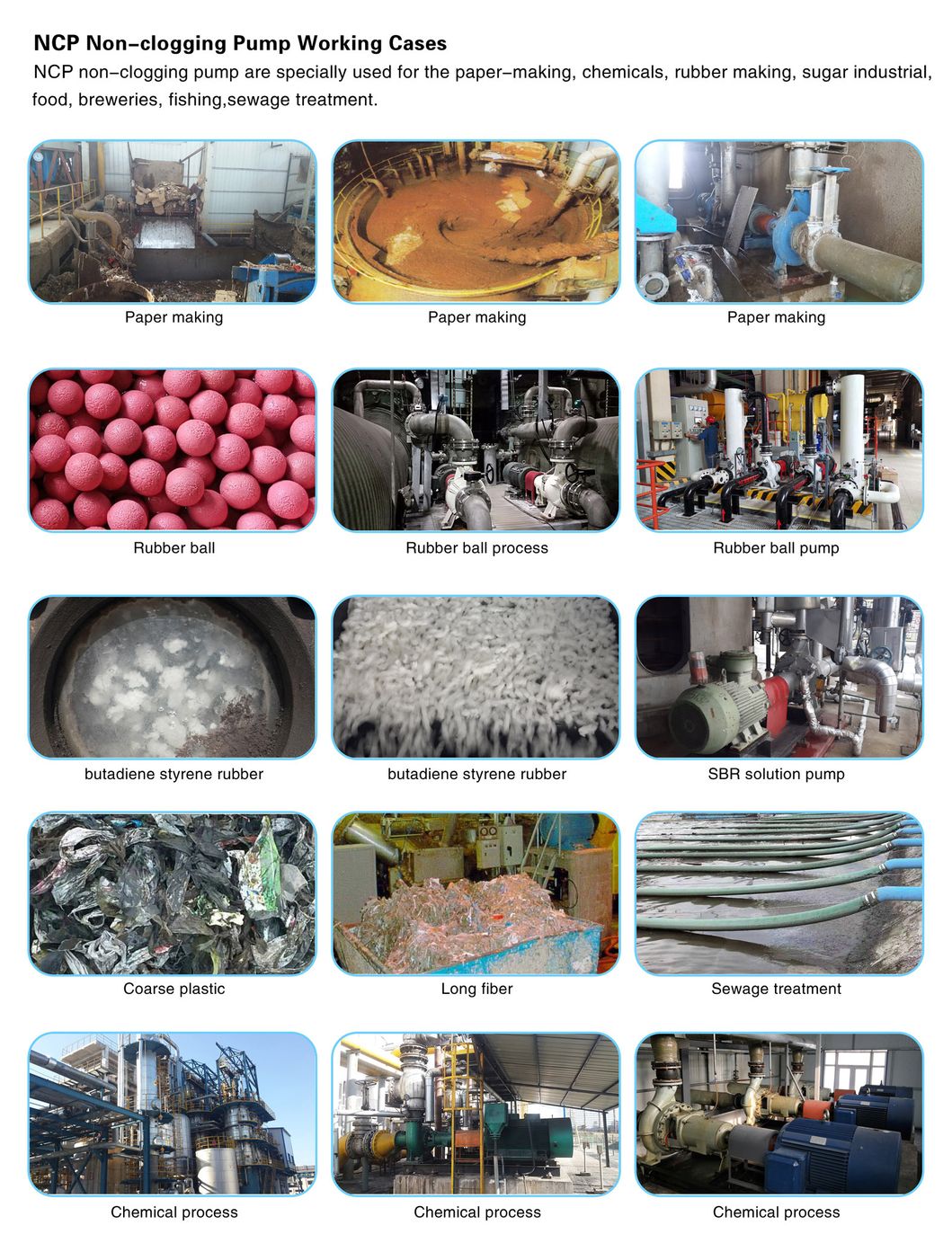

ApplicationsNCP non-clogging centrifugal pump is a solids handling pump for all kind of containing abrasive, long fiber, Coarse particles, rubber ball, waste water.The pumps are widely used for papermaking, brewery, food, sugar industry, Fishery industry, kitchen treatment, sewage treatment, biogas ......

Send Inquiry

Product Description

Applications

NCP non-clogging centrifugal pump is a solids handling pump for all kind of containing abrasive, long fiber, Coarse particles, rubber ball, waste water.

The pumps are widely used for papermaking, brewery, food, sugar industry, Fishery industry, kitchen treatment, sewage treatment, biogas engineering, chemical industry, environmental protection engineering and other industries.

Properties

Discharge diameter 40~500 mm

Flow 10~3800 m3/h

Head 7~90 m

Lubrication Oil

Rotating Clockwise

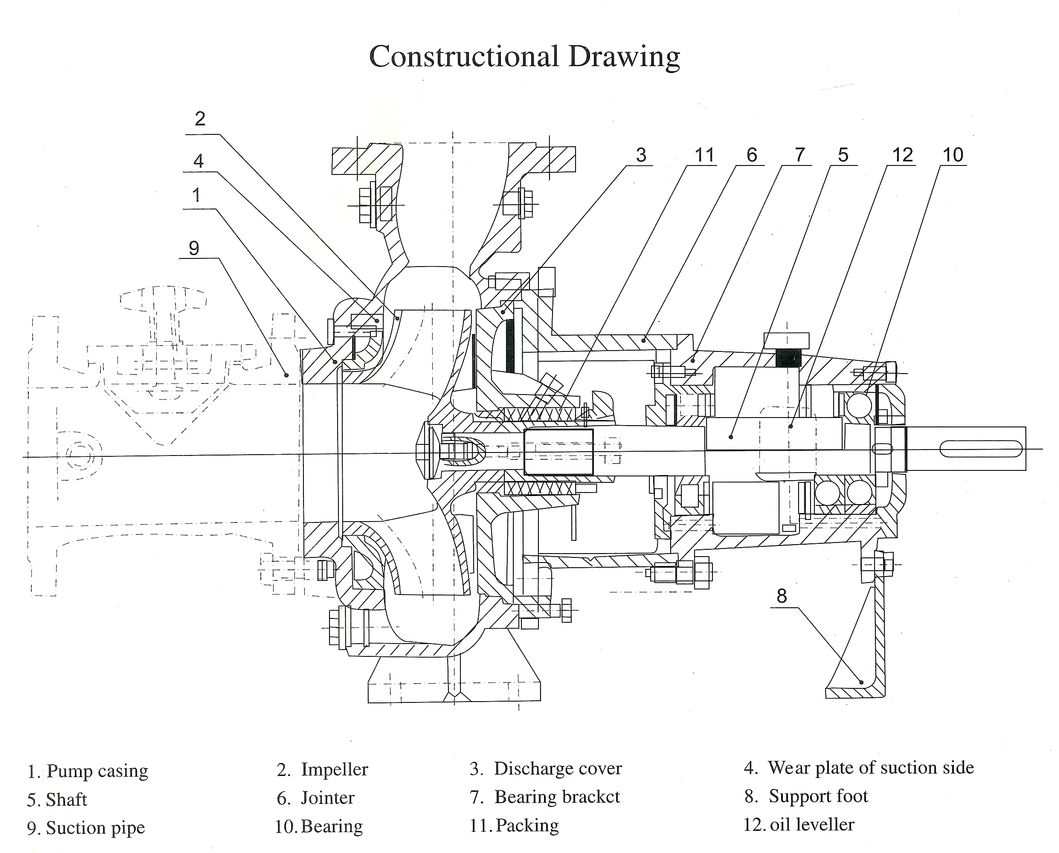

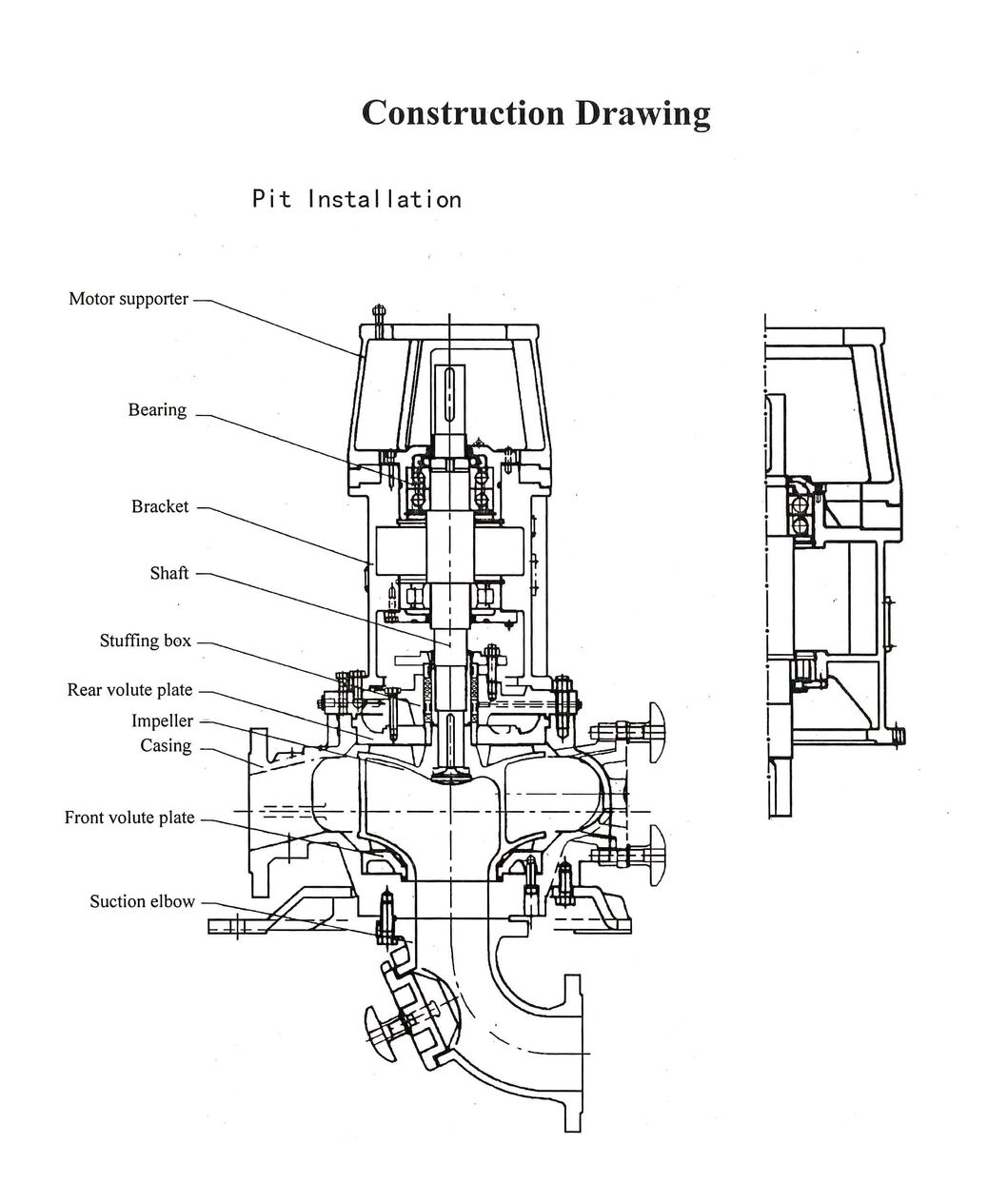

Construction and Feature

The NCP pump is of single-stage, centrifugal pump, It has the features of high efficiency, non-clogging and back pull-out design which can allow the rotor to be removed from the pump casing without disturbing the pipe or dismantling the casing. This not only simplifies maintenance but also allows fast inter change of the impeller and wear plate of suction side, thereby permitting the pump to be rapidly modified to suit different operating condition.

According to the diameter of discharge, the NCP pump can be divided form 40mm to 500mm.

The NCP pump normally is suitable for delivering the normal media(PH value is about 1~12). For the application of corrosive fluid and other special requirement, please quote this information when making order.

Impeller

NCP pumps are supplied with four kinds of impeller for suction.

K impeller--- Closed non-clogging impeller

With Wide flow channel, For clear water, sewage, sewage mud and medium containing solid.

N impeller--- Closed multi-vane impeller.

For clear water, Pulp, sugar juice, oil wastewater and media containing solid suspension.

O impeller--- Open impeller.

Same application as N impeller but also including fluids containing gas.

F impeller--- Free flow impeller.

For handle large and long solids.(such as long fiber, sticky particles, paper pulp , rubber balls and so on)and fluids containing air.

Shaft seals

There are three types of shaft seals for KWP pumps:

Packing seal

High temperature packing seal

Mechanical seal

Easy to service

It has the features of back pull-out design which can allowed the rotor to be removed form the pump casing without disturbing the pipe or dismantling the casing. To ensure that the pump could operate at a high efficient duty point, a front volute plate or an impeller ring installed on the pump casing, as result of which the service life of the pump casing and the impeller could be lengthened and the maintenance cost could be lowered as well.

Material

| Pump parts | Paper making | Sea water | Acid medium | Sewage | Clear water |

| Pump casing | Stainless steel 304 | Stainless steel 2205 | Stainless steel 316L | Cast iron | Stainless steel 2Cr13 |

| Impeller | Stainless steel 304 | Stainless steel 2205 | Stainless steel 316L | Carbon steel | Stainless steel 2Cr13 |

| Shaft | Alloy steel 40Cr | Stainless steel 316L | Stainless steel 304 | Alloy steel 40Cr | Alloy steel 40Cr |

| Shaft sleeve | Stainless steel 304 | Stainless steel 2205 | Stainless steel 316L | Stainless steel | Stainless steel 2Cr13 |

Related products

Application

HS heavy duty slurry pumps are cantilevered, horizontal ,centrifugal pump. They are designed for handling abrasive, high density slurries in mining, metallurgical, coal, power plant, chemical industry, building material and other industrial departments, etc.

The pumps of this type also may be installed in multistage series. In order to meet different vertical height, long delivery distance, with the max pressure that outer pump casing can bear, this kind of pump can be linked in series to add head.

Properties

Flow 12 ~ 5300 m3 /h

Head 6~65 m

Lubrication Standard: Grease

Optional: Oil

Temperature 80ºC

Type Notation

150 HS - E

Frame Type

HS heavy duty slurry pump

Discharge Diameter

Construction and Feature

HS heavy duty slurry pump adopts double shell structure, Double-pump casing-structure is safe and low cost. This kind of pump, its outside pumpcasing bears pressure, the inside pumpcasing bears wear and abrasion. Meanwhile, double-pump casing structure can save cost and make easy maintain by just changing the worn internal parts.

The wet parts can be high-abrasion and wear chrome iron or rubber which can make service life longer and more stable. Customer can select material according to media and pipe layout.

The discharge branch can be positioned at intervals of 45°degrees by request and oriented to any eight positions to suit installations and applications.

The shaft seal adopt many kinds of sealing systems: packing seal, expeller dynamic seal, mechanical seal.

Type HS pump performance parameters

| TYPE | Flow (m3/h) | Head (m) | Speed r/min | Impeller Vanes | Allowable particle size (mm) |

| 20HS-B | 7.2~ 20 | 6.5~ 65 | 1200~3600 | 5 | 15 |

| 40HS-B | 18~ 48 | 8.5~ 58 | 1200~3200 | 5 | 19 |

| 50HS-C | 36~ 90 | 10~ 60 | 1300~2700 | 5 | 25 |

| 75HS-C(D) | 42~ 144 | 9.0~ 52 | 1000~2200 | 5 | 28 |

| 100HS-D(E) | 108~ 324 | 13~ 61 | 800~1600 | 5 | 44 |

| 150HS-E | 180~ 650 | 9.0~ 61 | 500~1140 | 5 | 63 |

| 200HSM-E | 350~ 1100 | 12~ 58 | 600~1100 | 5 | 65 |

| 200HS-ST | 360~1260 | 11~ 60 | 400~850 | 5 | 76 |

| 250HS-ST | 540~1440 | 9.5~ 65 | 300~800 | 5 | 86 |

| 300HS-ST | 720~2160 | 14~ 62 | 300~600 | 5 | 90 |

| 350HS-TU | 1080~2880 | 12~ 61 | 250~550 | 5 | 135 |

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.