Home > Products > Centrifugal Pump > High Pressure Horizontal Multistage Centrifugal Pump for High Building

High Pressure Horizontal Multistage Centrifugal Pump for High Building

High Pressure Horizontal Multistage Centrifugal Pump for High Building IntroductionThis series of pump is of sub-horizontal, multi-stage single-suction and centrifugal, using state-recommended hydromodule. The pump is efficient, reliable, and durable with low noise performance, easy maintenance and......

Send Inquiry

Product Description

High Pressure Horizontal Multistage Centrifugal Pump for High Building

IntroductionThis series of pump is of sub-horizontal, multi-stage single-suction and centrifugal, using state-recommended hydromodule. The pump is efficient, reliable, and durable with low noise performance, easy maintenance and wide scope of usage. Our pump is applicable to deliver those fluid without solid, particles or any other suspended stuff, water for instance. While oil and corrosive or solid-contained fulid can be pumped by means of material modification, sealing methods, and cooling system adding.

Features

1.High Efficiency and Energy saving

We have developed our unique technology for manufacturing, model designing and making, foundry techniques of hydraulic parts to assure their brightness, cleanliness, and accurate dimensions. So the actual efficiency are at least 2% higher than other general multistage centrifugal pumps

2Advanced process equipment

Every single processed part will have cleaned by means of advanced imported cleaning equipment for better assembling concern. Besides material inspection, hydraulic test, static balancing testing, all pump rotors beyond 6 grades will have axial movement tested controlled within 5 millisecond, and then the balancing test shall be made according to G2.5 grade. Recheck axial movement of all shafts after assembly to assure the quality of the pump.

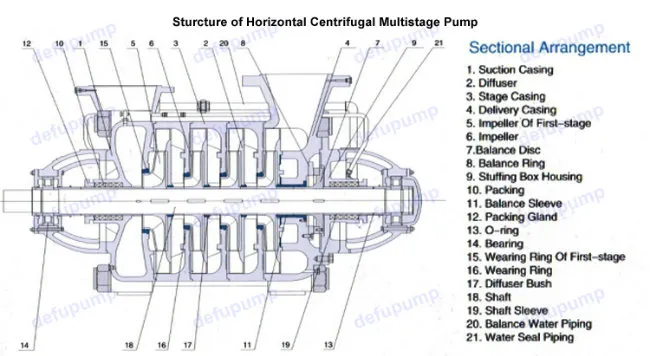

3.Unique structure

A sealing 0-ring is set between balancing ring and fitting surface of the pump to avoid high pressure water coming into balancing stage and wear and tear of the balabcing plate to obtain better durability,

4.Material choosing

Balancing plate and the eara around can be made of welding alloy,alloy steel or ductile cast iron QT600Mn2 concerning their high surficial hardness and fine durability, Flowing-over part of MD pump is of abrasion resistant by using material of alloy wear resistant ductile cast iron or high-grade wear-resistant ductile cast iron.

5.Fine appearance

The appearance of the pump is fine taking advantage of precise mold casting procedures and automatic painting.

Technical Parameters

| D(DF,DY,MD) 155-30× (2-10) / 150 D(DF,DY,MD) 30× (2-10) | |||||||||

| Stage | Capacity | Head | Rating Speed | Efficiency | Shaft power | NPSHr | Impeller Dia | Pump Weight | |

| m3/h | L/s | m | r/min | % | KW | m | mm | kg | |

| 2 | 119 | 33 | 64 | 1480 | 69.5 | 29.8 | 3.2 | φ305 | 476 |

| 155 | 43 | 60 | 75 | 33.71 | 3.9 | ||||

| 190 | 52.8 | 54 | 76 | 36.95 | 4.8 | ||||

| 3 | 119 | 33 | 96 | 1480 | 69.5 | 44.7 | 3.2 | φ305 | 546 |

| 155 | 43 | 90 | 75 | 50.57 | 3.9 | ||||

| 190 | 52.8 | 81 | 76 | 55.42 | 4.8 | ||||

| 4 | 119 | 33 | 128 | 1480 | 69.5 | 59.6 | 3.2 | φ305 | 617 |

| 155 | 43 | 120 | 75 | 67.42 | 3.9 | ||||

| 190 | 52.8 | 108 | 76 | 73.9 | 4.8 | ||||

| 5 | 119 | 33 | 160 | 1480 | 69.5 | 74.5 | 3.2 | φ305 | 687 |

| 155 | 43 | 150 | 75 | 84.28 | 3.9 | ||||

| 190 | 52.8 | 135 | 76 | 92.37 | 4.8 | ||||

| 6 | 119 | 33 | 192 | 1480 | 69.5 | 89.4 | 3.2 | φ305 | 757 |

| 155 | 43 | 180 | 75 | 101.1 | 3.9 | ||||

| 190 | 52.8 | 162 | 76 | 110.8 | 4.8 | ||||

| 7 | 119 | 33 | 224 | 1480 | 69.5 | 104.3 | 3.2 | φ305 | 827 |

| 155 | 43 | 210 | 75 | 118.0 | 3.9 | ||||

| 190 | 52.8 | 189 | 76 | 129.3 | 4.8 | ||||

| 8 | 119 | 33 | 256 | 1480 | 69.5 | 119.2 | 3.2 | φ305 | 897 |

| 155 | 43 | 240 | 75 | 134.8 | 3.9 | ||||

| 190 | 52.8 | 216 | 76 | 147.8 | 4.8 | ||||

| 9 | 119 | 33 | 288 | 1480 | 69.5 | 134.1 | 3.2 | φ305 | 968 |

| 155 | 43 | 270 | 75 | 151.7 | 3.9 | ||||

| 190 | 52.8 | 243 | 76 | 166.3 | 4.8 | ||||

| 10 | 119 | 33 | 320 | 1480 | 69.5 | 149.0 | 3.2 | φ305 | 1038 |

| 155 | 43 | 300 | 75 | 168.6 | 3.9 | ||||

| 190 | 52.8 | 270 | 76 | 184.7 | 4.8 | ||||

Application

Our Service

1.Delivery: Delivery time will be on time as the contact. Usually, the delivery time is of centrifugal pump is for 15-25 working days.

2.Warranty: 1 year for the pump body, 3 months for the main working parts.

3.Package:According to your quantity, we use plywood case which is durable for ocean transport.

4.Shipping: By Sea and By Air

5.Payment: We are accept T/T,L/C,West Union and so on.

6.Pre-sales Service:According to your requirement, we will give your our profession advice of pump solution.

7.On-sales Service:We will clearly show you everything in fact when you place an order with us. We will takes photos or videos to show you order production situation.

8.After-sales Service: We will full report you the production progress and plan. Meanwhile, we will follow up the pump working conditions per three months when the pumps put into use, and can send the spare parts to you within one week if you need.

About Us

Welcome to visit our company!

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.