High Head Slurry Pumps for Washing Plant 8/ 6e

Feature of ZJ-AH/ZJH-HH horizontal slurry pumps1.Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeab......

Send Inquiry

Product Description

Feature of ZJ-AH/ZJH-HH horizontal slurry pumps

1.Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

Shijiazhuang Naipu Pump CO.,LTD is a preofessional manufacturer in Shijiazhuang City,Hebei Province, we have our own casting workshop, foundry workshop ,machine workship and assemble workshop. We produce AH slurry pumps, normally from 1.5/1B-AH to 16/14TU-AH, and SP vertical slurry pumps from 40PV-SP to 200sv-sp, if larger pumps, please contact with us to discuss the details.Our slurry pumps sell we all around the world,especiall in South Africa, America, Russia,etc.

Producing process of our pumps and spare parts, first to make the molds by different methods, such as lost foam and then casting, heat treatment,machine and assemble.Our pumps do both static balance and dynamic balance

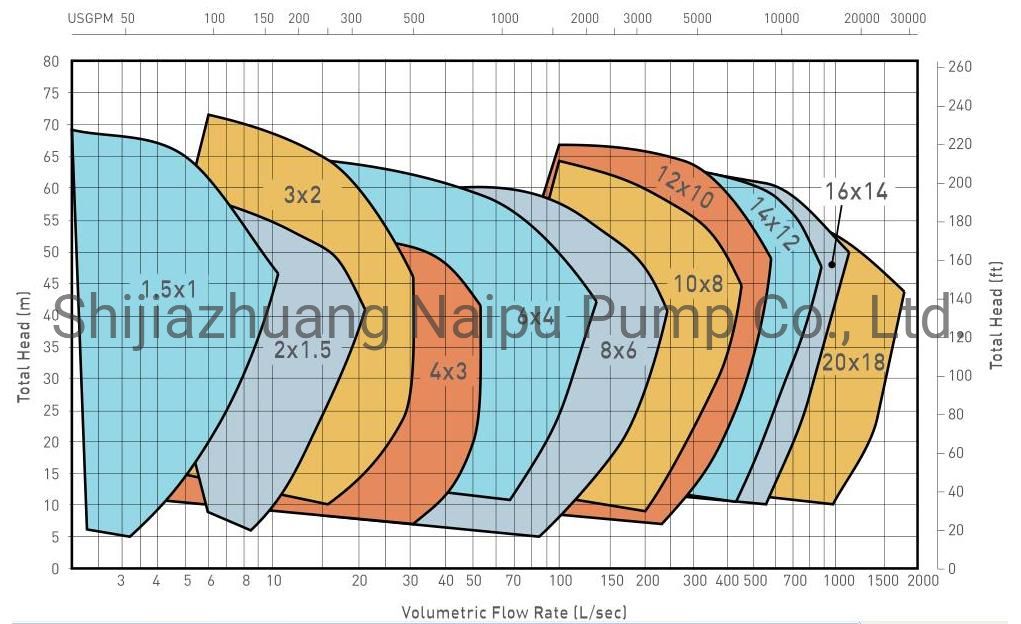

The performance range of our slurry pumps, if you need the detail performance, please email us.

Performance Sheet of Naipu pump ZJ-AH/ZJH-HH Series

Pump Model | Allowable Max. Power(KW) | Clear Water Performance | ||||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | Impeller Dia. | |||

| m3/h | l/s | |||||||

| 25ZJ-B | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| 25ZJR-B | 15 | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | ||

| 25ZJH-C | 30 | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

| 40ZJ-B | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| 40ZJR-B | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

| 50ZJ-C | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| 50ZJR-C | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 2-4 | 213 | |

| 50ZJH-D | 60 | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| 75ZJ-C | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 75ZJ-D | 60 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 75ZJR-C | 30 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 75ZJR-D | 60 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 100ZJ-D | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 100ZJ-E | 120 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 100ZJR-D | 60 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 100ZJR-E | 120 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 100ZJH-F | 260 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| 150ZJ-E | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 150ZJ-S | 300 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 150ZJR-E | 120 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 150ZJR-R | 300 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 150ZJH-S | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

| 200ZJ-ST | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| 200ZJR-ST | 560 | 540-1188 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 686 |

| 200ZJ-E | 120 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 200ZJ-R | 300 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 250ZJ-ST | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

| 250ZJR-ST | 560 | 720-1620 | 320-700 | 13-14 | 300-500 | 79 | 3-8 | 762 |

| 300ZJ-ST | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| 300ZJR-ST | 560 | 1152-2520 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 965 |

| 350ZJ-ST | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| 400ZJ-TU | 1200 | 2160-5054 | 600-1400 | 8-66 | 200-500 | 80 | 4.5-9 | 1245 |

| 450ZJ-TU | 1200 | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

Performance curves of our pumps

Drive type of our slurry pumps