D, MD Horizontal High Pressure Multistage Centrifugal Pump

ApplicationType D multi-stage clean water pump is a horizontal, single suction, multi-stage, segmental centrifugal pump. It is suitable for transporting clean water without solid particles or neutral liquid with physical and chemical properties similar to clean water. The medium temperature is lower......

Send Inquiry

Product Description

Application

Type D multi-stage clean water pump is a horizontal, single suction, multi-stage, segmental centrifugal pump. It is suitable for transporting clean water without solid particles or neutral liquid with physical and chemical properties similar to clean water. The medium temperature is lower than 80 ºC. It is suitable for water supply and drainage in cities, factories and mines, and farmland irrigation and drainage.

Type DL multi-stage clean water pump is a vertical, single suction, multi-stage, segmental centrifugal pump.

Type MD multistage pump is a mine wear-resistant multi-stage pump, which is based on D type pump. The flow passage parts are made of wear-resistant materials, which have the characteristics of good cavitation resistance, wear-resistant, energy-saving and long service life. It is suitable for conveying sewage containing a small amount of solid particles (particle size less than 1 mm), mine precipitation water, or neutral liquid with physical and chemical properties. The medium temperature is lower than 40 ºC. It is suitable for iron ore, coal mine and factory to discharge sewage containing impurities.

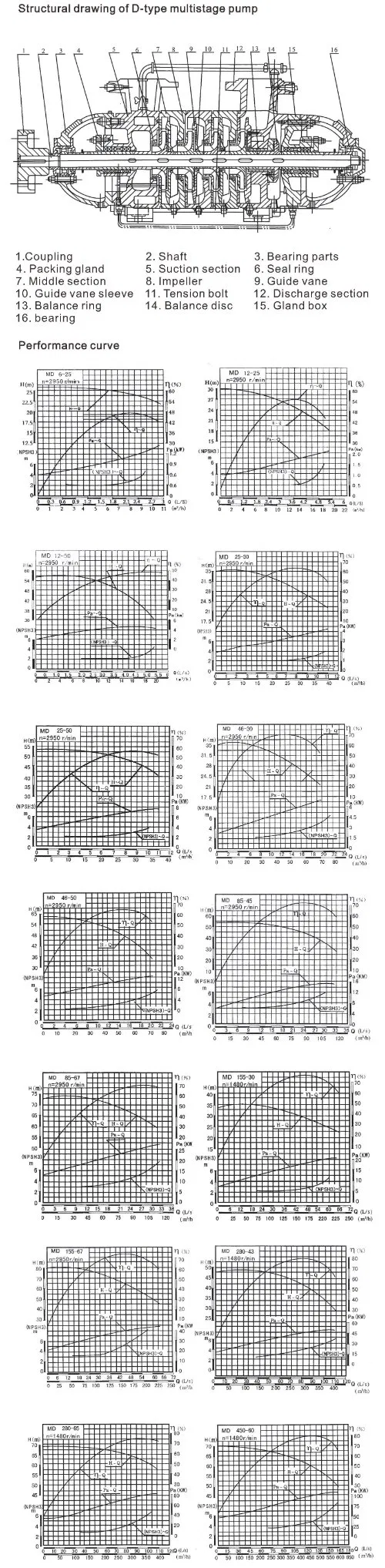

Performance range

Flow: 6.3~500 m3 /h

Head: 50~650 m

Lubrication: oil

Type Notation

D(MD) 155-30×7

D ― Multistage water pump

MD ―Mine wear resistant multistage pump

155 ― Flow capacity (m3/h)

30 ― Head (m)

7 ― Stage of pump

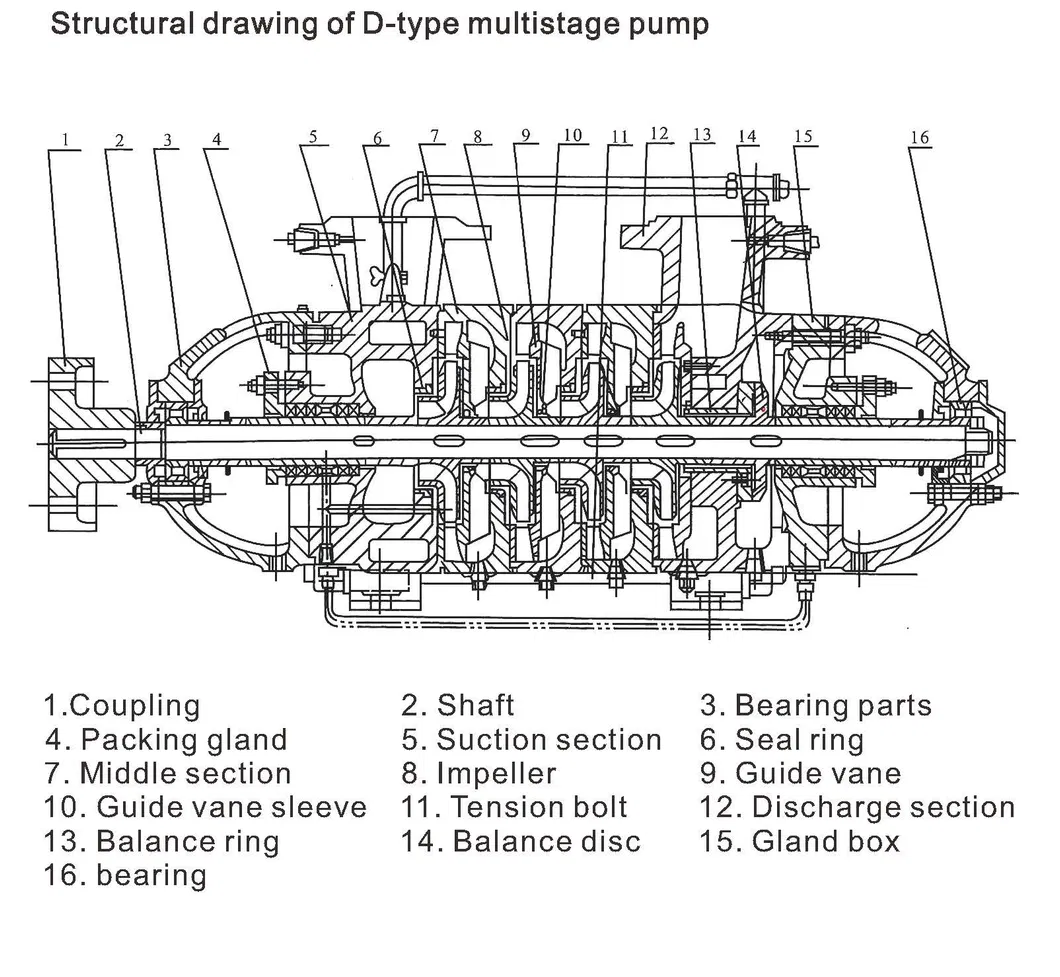

Construction and Feature

- D-type multi-stage pump is mainly composed of working chamber, rotor parts, bearing parts, shaft seal device, balancing device and transmission device.

- The turning direction of the pump, viewed from the driving end, is clockwise.

- Applicable power supply: 50Hz or 60Hz

- Driving mode: Motor or Diesel engine

- The balance device ensures the effective balance of the axial force of the pump.

Material:

| medium | material |

| Clear water | Cast iron, 304 |

| River water | Cast iron, 2Cr13 |

| Sewage water | Cast iron, Cast steel, 2Cr13, 304 |

| Mine sewage | 2Cr13, 304, high chrome cast |

| Sea water | 316L, CD4MCu, 2205, 2507 |

Performance Data of D MD Multistage Pump

| Pump Type | Flow Q (m3/h) | Head H (m) | Speed n r/min | Allowable max. power (KW) | Outlet/Inlet (mm) |

| D 6 -25×3~12 | 3.7~7.5 | 75~300 | 2950 | 5.5~18.5 | 40 / 40 |

| D 12 -25×3~12 | 7.5~15 | 75~338 | 2950 | 7.5~30 | 40 / 50 |

| D 12 -50×3~12 | 9.0~15 | 150~600 | 2950 | 18.5~55 | 50 / 50 |

| D 25 -30×3~10 | 15~30 | 90~300 | 2950 | 15~45 | 65 / 65 |

| D 25 -50×3~12 | 15~30 | 150~600 | 2950 | 30~110 | 65 / 65 |

| D 25 -80×2~12 | 17.4~29 | 159~908 | 2950 | 30~160 | 65 / 80 |

| D46 -30×3~10 | 30~55 | 90~260 | 2950 | 22~75 | 65 / 80 |

| D46 -50×3~12 | 30~55 | 150~600 | 2950 | 37~132 | 80 / 80 |

| D50 -80×2~12 | 32~66 | 165~988 | 2950 | 55~315 | 80 / 100 |

| D85 -45×2~9 | 55~100 | 90~450 | 2950 | 37~160 | 100 / 100 |

| D85 -67×3~9 | 55~100 | 201~603 | 2950 | 90~250 | 100 / 100 |

| D100 -80×2~12 | 50~131 | 165~994 | 2950 | 90~500 | 125 / 125 |

| D120 -50×2~9 | 96~140 | 100~450 | 2950 | 55~220 | 125 / 125 |

| D155 -30×2~10 | 100~185 | 60~300 | 1480 | 55~220 | 150 / 150 |

| D155 -67×3~10 | 100~185 | 201~603 | 2950 | 132~400 | 150 / 150 |

| D280 -43×2~9 | 185~335 | 86~387 | 1480 | 110~450 | 200 / 200 |

| D280 -43×2~9 | 185~335 | 86~387 | 1480 | 250~450 | 200 / 200 |

| D280 -65×3~10 | 185~335 | 195~650 | 1480 | 110~800 | 200 / 200 |

| D360 -40×2~10 | 300~440 | 80~400 | 1480 | 132~630 | 200 / 200 |

| D450 -60×2~10 | 355~500 | 120~600 | 1480 | 220~1120 | 250 / 250 |

| D580 -60×3~10 | 450~638 | 180~600 | 1480 | 450~1250 | 250 / 250 |

Related Products

Metal structure

Rubber structure

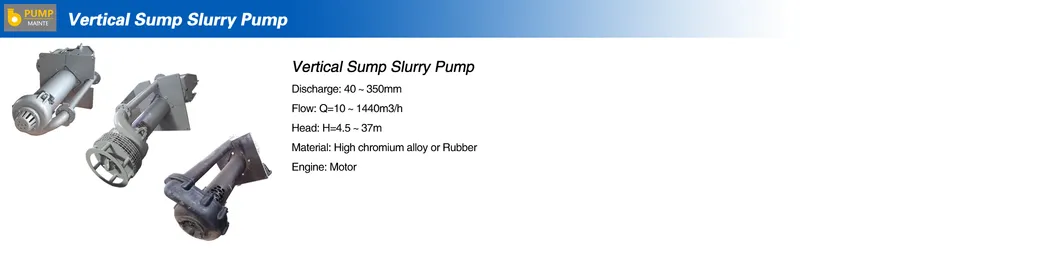

Related Products

Applications

Type SP and SPR pump are vertical, centrifugal slurry pump submerged in sump to work. They are designed for delivering abrasive, large partical and high density slurries. This pump have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.

Type SP and SPR vertical pumps are widely used in power plants, steel, mining, metallurgy, building materials, desulfurization and other industries.

Wet parts of are make of abrasion-resistant metal or rubber.

Type Notation

65QV-SP(SPR)

SP(SPR)-----Slurry pump submerged in sump

QV-----Frame Type

65-----Outlet Diameter

Construction and feature

Type SP all metal for abrasive duty

Type SPR elastomer protected for acid /abrasive duty

The pump has an extended shaft structure, which is suitable for the working condition of deeper level.

The pump can extend the suction pipe.

The pump can be with agitator.

Type SP and SPR selection performance datasheet

| TYPE | Flow (m3/h) | Head (m) | Speed r/min | Standard submerged depth (mm) | allowable particle size (mm) |

| 40PV-SP(R) | 10~ 36 | 4.5~ 30 | 1000~2200 | 900 | 12 |

| 65QV-SP(R) | 25.2~ 90 | 5.0~ 31 | 700~1500 | 1200 | 15 |

| 100RV-SP(R) | 54~216 | 5.0~ 37 | 500~1200 | 1500 | 32 |

| 150SV-SP(R) | 180~468 | 4.0~36 | 500~1000 | 1500 | 45 |

| 200SV-SP(R) | 252~720 | 7.2~ 35 | 400~850 | 1800 | 65 |

| 250TV-SP | 432~980 | 9.0~ 33 | 400~750 | 1800 | 65 |

| 300TV-SP | 540~1080 | 7.0~ 33 | 350~700 | 1800 | 65 |

| 350TV-SP | 720~1440 | 8.0~ 32 | 350~700 | 1800 | 75 |

---FAQ---

Q: How to customize pumps and mechanical seals?

A: Customers could send us application data, such as:

Liquid:

Capacity: m3/hr, Head: m

Voltage: V, Frequency: Hz

We will select suitable pump and seal type.

Q: How can I pay for my items? What is the payment you can provide?

A: Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment. L/C at sight.

Q: How long is warranty?

A: 12 months.

Q: How long is production lead time?

A: Normally 15 working days. If client need urgently, we have a huge spare part stock, we could finish assembly and testing in 10 days.

Q: Can you send the pump to our country?

A: Of course, Please advise destination port or your address.

Q: What is the shipping terms you can provide?

A: Depends on customer's requirements, we can provide different transportation terms, such as EXW, FOB, CIF.

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.