Home > Products > Centrifugal Pump > Anti Abrasion Wet Pit Dewatering Slurry Pump Vertical Sludge Lifting Pump

Anti Abrasion Wet Pit Dewatering Slurry Pump Vertical Sludge Lifting Pump

Vertical Slurry Pump Specification :Outlet Diameter:40mm to 300 mm Q: up to 1267 m3/hr H: up to 40 m ZV/ ZVR CLEAR WATER PERFORMANCEMODELMAX.POWER (KW) MATERIALQ - CAPACITY HEADH(m) SPEEDn(r/min) MAX.Effη%LINERIMPELLER(m 3 /h)(I/S)ZV-40P15......

Send Inquiry

Product Description

Vertical Slurry Pump Specification :

Outlet Diameter:40mm to 300 mm

Q: up to 1267 m3/hr

H: up to 40 m

| ZV/ ZVR CLEAR WATER PERFORMANCE | ||||||||

| MODEL | MAX. POWER (KW) | MATERIAL | Q - CAPACITY | HEAD H(m) | SPEED n(r/min) | MAX.Eff η% | ||

| LINER | IMPELLER | (m 3 /h) | (I/S) | |||||

| ZV-40P | 15 | M | M or RU | 19.44~43.2 | 5.4~12 | 4.5~28.5 | 1000~2200 | 40 |

| ZVR-40P | 15 | RU | RU | 17.28~39.6 | 4.8~11 | 4~26 | 1000~2200 | 40 |

| ZV-65Q | 30 | M | RU | 23.4~111 | 6.5~30.8 | 5~29.5 | 700~1500 | 50 |

| ZV-65Q | 30 | M | M | 19.8~93.06 | 5.5~25.85 | 5~29.5 | 700~1500 | 40 |

| ZV-65Q | 30 | M | M | 23.4~87.12 | 6.75~24.2 | 5.5~31.5 | 700~1500 | 58 |

| ZVR-65Q | 30 | RU | RU | 22.5~105 | 6.25~29.15 | 5.5~31.5 | 700~1500 | 51 |

| ZV-65Q | 30 | M | M | 18.9~89.1 | 5.25~24.75 | 5~28 | 700~1500 | 35 |

| ZV-100R | 75 | M | RU | 56.7~221.76 | 15.75~61.9 | 4.5~34.5 | 500~1200 | 56 |

| ZV-100R | 75 | RU | RU | 64.8~285 | 18~79.2 | 7.5~36 | 600~1200 | 62 |

| ZVR-100R | 75 | M | M | 54~289 | 15~80.3 | 5~35 | 500~1200 | 56 |

| ZV-100R | 75 | M | M | 54~237.6 | 15~66 | 6~30 | 600~1200 | 40 |

| ZV-150S | 110 | M | RU | 108~479.16 | 30~133.1 | 8.5~40 | 500~1000 | 52 |

| ZV-200S | 110 | M | M or RU | 189~891 | 52.5~247.5 | 6.5~37 | 400~850 | 64 |

| ZV-250T | 200 | M | M or RU | 261~1089 | 72.5~302.5 | 7.5~33.5 | 400~750 | 60 |

| ZV-300T | 200 | M | RU | 288~1267 | 80~352 | 6.5~33 | 350~700 | 50 |

ZV Vertical Slurry Pump Introduction:

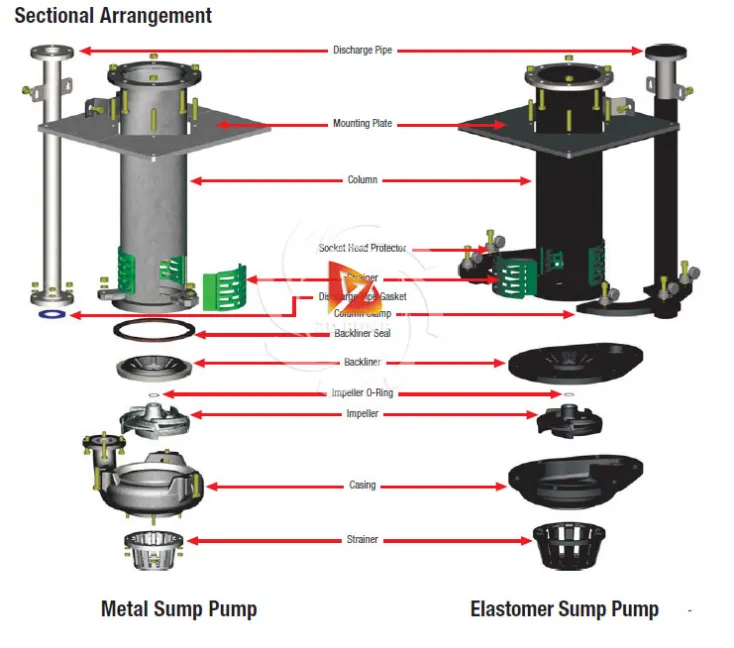

The ZV, ZVR range is of a vertical cantilevered design that features hard alloy wear parts or full elastomer protection

on all submerged components. This allows this pump to be used in highly corrosive applications. Available in sizes

40mm (1.5 inches) up to 300 mm (12 inches).

ZV,ZVR type submerged slurry pumps are mainly applicable to transport abrasive, coarse particle, high concentration slurry.

They are widely used in metallurgy, mining, coal, electric power, building materials, environmental protection

and other departments.

ZV Vertical Slurry Pump Features:

1. The rotor parts can be adjusted axially and supported by multiple points, so heavy duty cantilever sump pump

can operate steadily and reliably.

2.The pump adopts a long shaft structure and can be inserted deeply inside water level. Shaft coupling is safe and reliable.

Convenient disassembly.

3. The impeller is immersed in the medium when the pump starts, so it is easy to start, and there is no air exhaust problem.

4.The outlet flange is a half movable flange for easy connection .

Vertical Slurry Pump Parts Material:

| Description | Standard Material | Material Options |

| Shaft | 4140 Mild Steel | Available on Request |

| Bearing Housing | Cast Iron | |

| Column | Mild Steel | |

| Upper Strainer | Rubber | Cast Iron |

| Lower Strainer | Cast Iron | |

| Back Liner | 27% Chrome White Iron | |

| Pump Casing | 27% Chrome White Iron | Rubber Lined White Iron |

| Impeller | 27% Chrome White Iron | Rubber |

| Discharge Pipe | Mild Steel | Rubber Lined Mild Steel/ Composite |

| Adaptor Plate | Mild Steel |

Slurry Pump Typical Application:

| • Mineral processing | • Mining Dewatering | • Coal Washery | • Cyclone feeds |

| • Bentonite | • Chemical slurry | • Tailings | • Mill grinding |

| • Ash handing | • Tunnel | • Waste sludge | • Coarse sand |

| • Lime mud | • Phosphoric acid | • Dredging | • Construction |

| • Alumina Industry | • Power Plant | • Potash Fertilizer Plant | • Other industries |

| • Iron ore sand | • Copper Concentration | • Gold mine | • Molybdenum |

FAQ :

A: What kind of company you are?

Q: We are centrifugal pump manufacturer located in ShiJiazhuang city,Hebei province,China, with more than

20years experiences. We were gaining good reputation among our customers for our professional,

warm and thoughtful service. Because we know that a long terms business is based on Quality + price + Packing +

delivery + after sale service ,etc.

A: What's the quality assurance you provided and how do you control quality?

Q: Established a procedure to check products at all stages of the manufacturing process: Casting, Heat treatment,

Machining, Assembly, and Testing. We strictly following instructions of ISO9001 quality management systerm to

make sure each parts are good quality under controlled.And also we welcome 3rd party inspections.

Q: What's your MOQ?

A: MOQ is 1 set as trial order.

Q: What are your payment terms?

A: T/T, L/C, West Union, Paypal,etc.

Q: How about the warranty?

A: One year warranty for the whole set pumps.

Q: What is the delivery time?

A: 10-20days according to customer quantities.

Q: Can you do OEM service?

A: Yes, OEM is Welcome.

For more details on wet pit dewatering slurry pump vertical sludge lifting pump, welcome contact us.

We will give you technical reply ASAP!

Related Category

Water Pump

Centrifugal Pump

Plunger Pump

Piston Pump

Diaphragm Pump

Gear Pump

Vacuum Pump

Pump Parts

Screw Pump

Gasoline & Gas Pump

Self-Priming Pump

Vane Pump

Other Pump & Vacuum Equipment

Pressure Pump

Jet Pump

Peristaltic Pump

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.